Technical data:

1. Bag speed:15-20bags/min(the speed is related to different SKU)

2.Packing bag thickness:0.05mm—0.09mm

3.Packing bag material:OPP, CPP,PE,complex film

4. Electrical supply: 220V,50HZ

5. Air supply voltage:0.6MPA

6.Gross power:0.4KW

7. Packing size after packing:Length:10-45dm

Width:14-28dm

Height:5-18dm (can be customized if needed)

8. Weight: 400KG

9.Machine footprint requirement:2100mm×1250mm×1250mm

Advantage:

1.Used for medical pad,underpad,nursing pad,diaper,pet pad bagger.The bagging method can be flat.

2.Full-servo control automation system,shorten debugging period,save operator, lower material,lower labor costs.

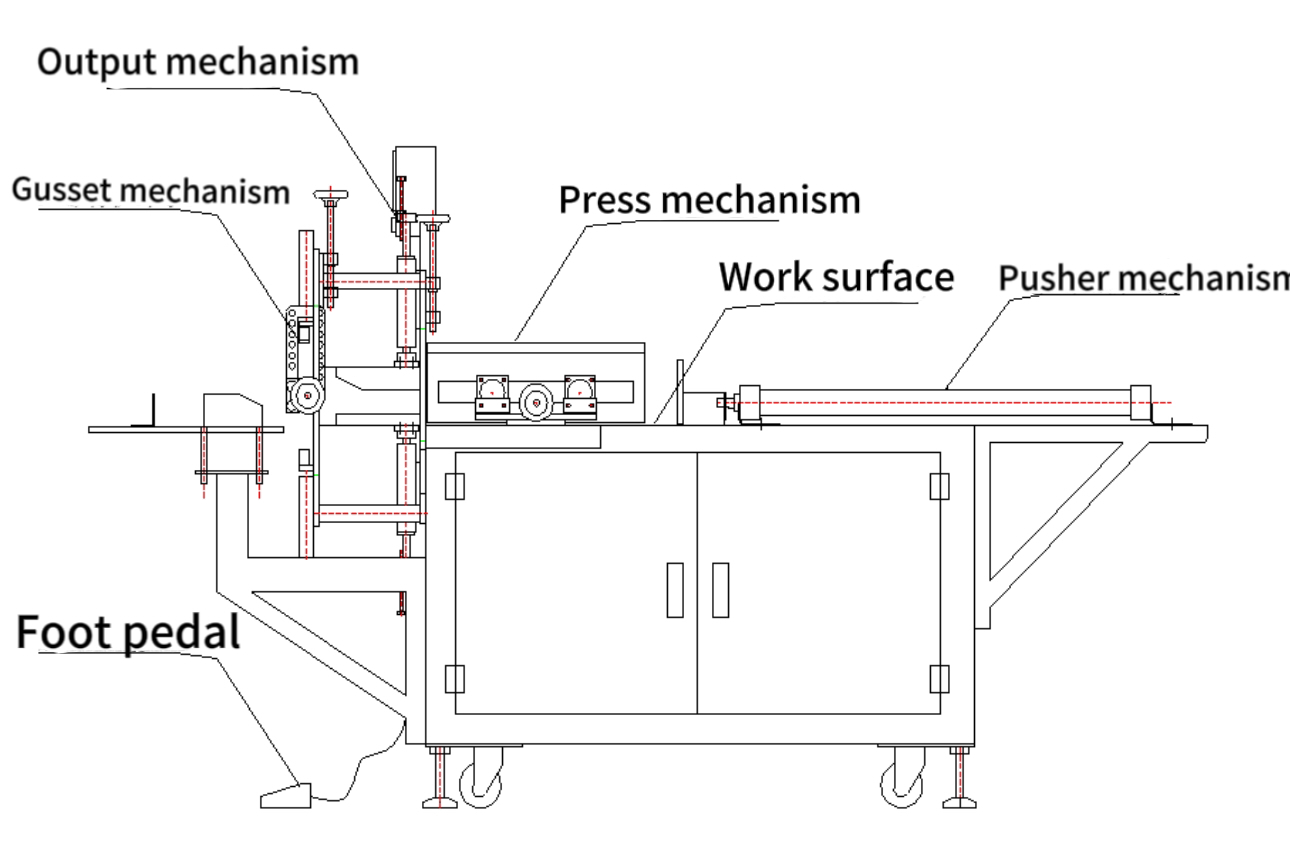

3.Flexible:wheels can be added to the machine to move from position A to position B.

4.Bag sealing integrity: guesset offset range 1 to 3mm.

5.Induction before working , more safe to operate,can be used for various products packaging.